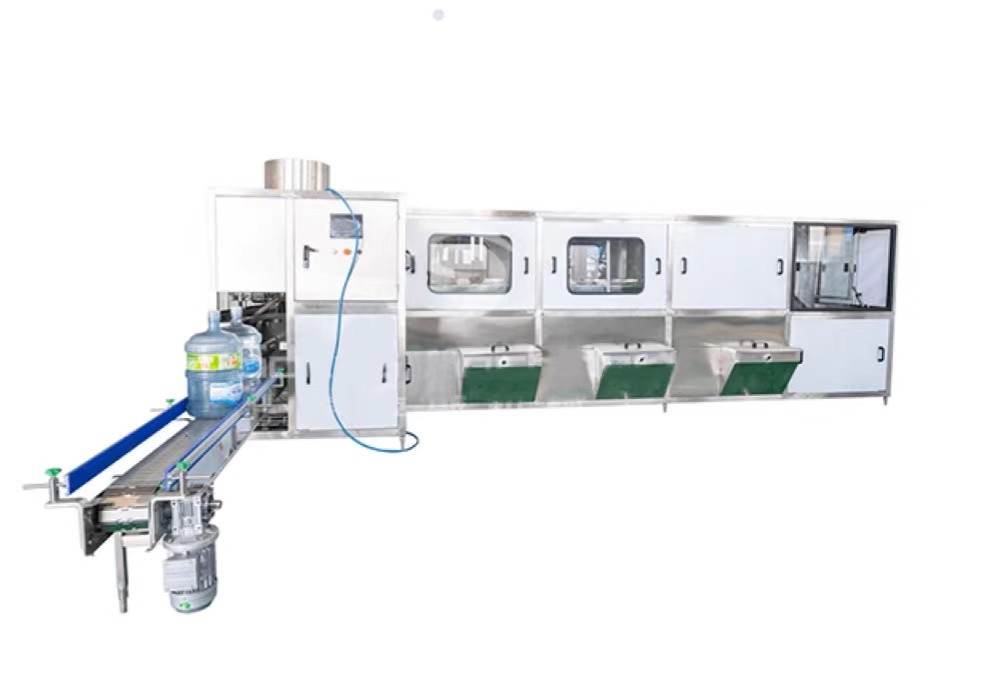

Automatic 5 gallon Barrel Pure Water Filling Machine

Overview

QGF series is special for 3&5 gallon drinking water production line which is ancillary equipment for filling mineral water. It can effectively wipe off the mineralization precipitate , and all-round washing the outer, inner and bottom of the barrel, which increase the washing result and reduce secondary pollution of manual work as well as the labor intensity of operating worker. The main material is stainless steel which is corrosion resisting and easy to clean. It can Main electric original uses SIEMENS,OMRON brand, and gas circuit uses AIRTAC brand products. The whole machine has compact structure, high and stable work efficiency, correct and sensitive motion, high degree of automation, which is a trinitarian ancillary equipment.

Final Product

Product Paramenters

|

Type |

Automatic 5 gallon water filling machine |

|

Colour |

Sliver Grey |

|

Usage |

Liquid Filling &Packing |

|

Filling Valume |

18.9l-20l |

|

Rinsing pressure |

0.2~0.3Mpa |

|

Power |

3ph,380V/50Hz,1.5~11.5KW, |

Washing

- Into bottle way is air conveyor direct connection with bottle dial.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

Filling

- 304/316 Stainless steel high precision filling nozzle

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

Capping

- Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%