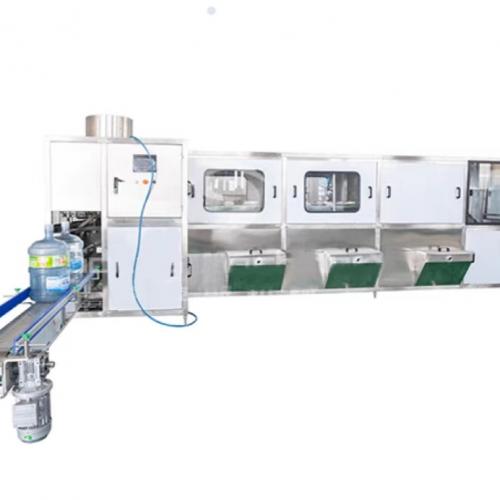

2000BPH Automatic Rotary 2-in-1 Pet Bottled Oil Filling Machine

Overview

This pet bottle juice plup filling machinery has washer,filler,capper three functions in one body, total process is automatic.

It is suitable for high temperature resistant PET bottled juice and tea drink filling.

It applies advanced micro-pressure gravity type filling principle, with perfectrecirculation system, also can reach separately gas return, without contacting with material, avoid secondary pollution and oxygen.

It is made of high quality SUS304 stainless steel. Main components of this fruit juice packaging machine are processed precisely by CNC machine tool.

Final Product

Product Paramenters

|

Type |

Automatic bottled oil filling machine |

|

Colour |

Sliver Grey |

|

Usage |

Liquid Filling &Packing |

|

Filling Valume |

300ml-2000ml |

|

Rinsing pressure |

0.2~0.3Mpa |

|

Power |

3ph,380V/50Hz,1.5~11.5KW, |

Machine Parameters

| Model | RCGF 8-8-4 | RCGF 14-12-5 | RCGF 18-18-6 | RCGF 24-24-8 |

| Washing head | 8 | 14 | 18 | 24 |

| Filling head | 8 | 12 | 18 | 24 |

| Capping head | 4 | 5 | 6 | 8 |

| Production capacity | 2000bph | 3500bph | 8000bph | 10000bph |

| Bottle height | 330mm | 330mm | 330mm | 330mm |

| Bottle diameter | 50~100mm | 50~100mm | 50~100mm | 50~100mm |

| Bottle volume | 0.2~2L | 0.2~2L | 0.2~2L | 0.2~2L |

| Rinsing pressure | 0.2~0.3Mpa | 0.2~0.3Mpa | 0.2~0.3Mpa | 0.2~0.3Mpa |

| Rinsing water consumption | 0.5T/H | 0.5T/H | 0.5T/H | 0.5T/H |

| Filling precision | ±2~3% | ±2~3% | ±2~3% | ±2~3% |

| Power | 3ph,380V/50Hz,1.5Kw | 3ph,380V/50Hz,1.5Kw | 3ph,380V/50Hz,2Kw | 3ph,380V/50Hz,3Kw |

Filling

- 304/316 Stainless steel high precision filling nozzle

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

Capping

- Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%